cadmeister-thai@uelthai.co.th

The standard functions for creating NC data are provided in order to support 3-axis Machines, Table 5-axis Machines, and Attachment 5-axis Machines as well as meet individual requirements of machining.

Customizable templates of machining instruction manual are also provided.

Thus, it is possible to create data that fit the requirements out in the manufacturing field.

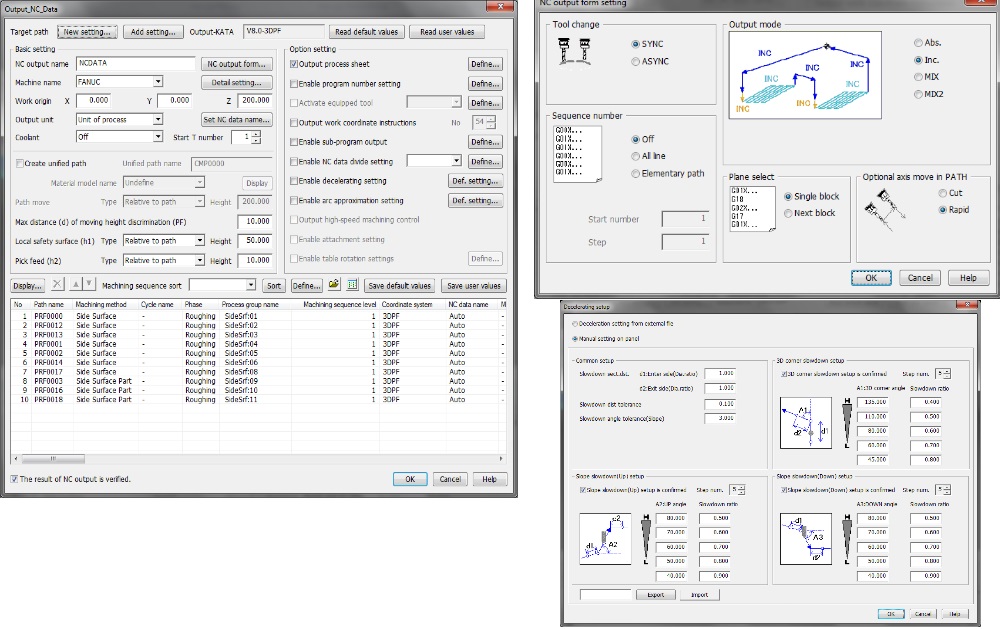

There are a wide variety of commands for creating NC data such as the commands for: adjusting feeding speed through the use of approximate arc and inclination of corner; dividing NC data mainly through the use of cutting length and file size; and outputting NC Data in the form of main program or sub program.

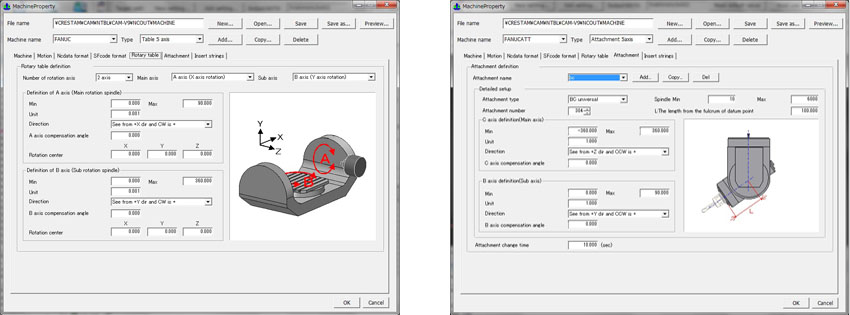

Post Settings enable various types of settings that match individual machines. They include the settings such as NC data output forms and tool replacement instructions.

Post Settings support the settings for a 5 fixed-axis device by executing the commands for: revolving a table and machining inclined surfaces, replacing and revolving an accessory for angle adjustment (referred to as an 'Attachment'), and converting 3D coordinates.

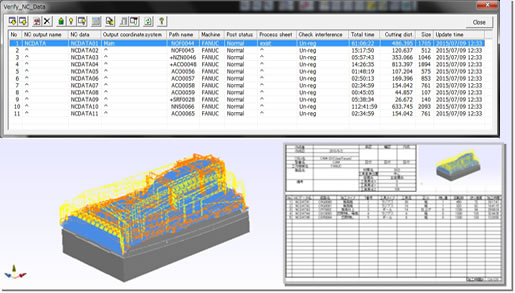

Various methods for NC data confirmation are enabled partly through the execution of the commands for: re-executing, confirming and editing NC text data, displaying tool loci, checking interference between a tool with a blade and die/mold shapes, and confirming machining instruction manuals.

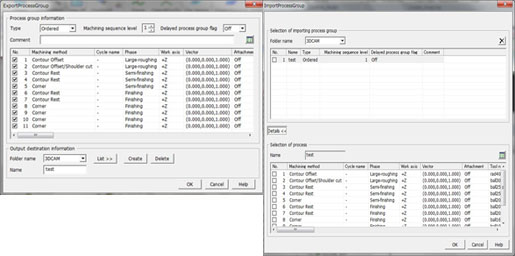

Phases of machining and process schedules can be saved and imported into a machining database, provided that they have been standardized.

Paths can be created by simply entering the minimum necessary inputs, provided that process schedules have been standardized and templatized. Thus, work hours can be significantly shortened and path quality can be homogenized.

UEL (Thailand) Co.,Ltd.